From the elaborate design of building walls to the architectural honesty of ceilings, devices like the metal wall panel machine and metal ceiling perforation line are at the center of advancement. These machines simplify the construction and processing of numerous metal components, making certain effectiveness and quality that satisfies the high standards of today's commercial demands.

The relevance of coil perforation lines can not be overstated, as they facilitate the processing of metal coils right into functional sheets or components with pre-determined openings. This procedure considerably boosts the versatility in design and application, satisfying varied industries such as building, auto, and home devices. The precision supplied by such machines makes sure that each perforation is executed with precision, therefore minimizing waste and making best use of resource use. Coupled with improvements in modern technology, today's sheet metal perforating machine can achieve broadband and performance, enabling large production without jeopardizing top quality.

In addition, as design looks become a progressively significant element in design, the need for metal ceiling tiles has risen. This is where the ceiling T-grid machine comes into play. By automating the production of T-grids, it streamlines the installment of put on hold ceilings, providing not only practical assistance for the ceiling floor tiles but likewise enhancing the general layout without the included complexity of manual work. The precision design associated with these equipments ensures seamless connections and positionings, which are vital for the completed look of any type of area.

To further improve metal construction capabilities, producers often depend on auxiliary equipment such as the metal sheet leveling machine and sheet metal straightening machine. These machines play a vital function in making sure that metal sheets are level and cost-free from any kind of bending or issues, which can bring about concerns in succeeding handling phases. A well-leveled sheet is extremely important in applications calling for accuracy, as also minor discrepancies can negatively influence joint honesty in welding or minimize effectiveness in subsequent reducing processes.

As we dig much deeper right into the effectiveness of these makers, it deserves keeping in mind that the advancement in digital technology has produced a new era in the operation of metal processing devices. Lots of makers today are furnished with CNC (Computer Numerical Control) systems, permitting better automation, accuracy, and personalization. This transition to CNC-controlled metal sheet perforating equipments and perforation lines enhances the manufacturing procedure by allowing drivers to quickly change specifications and settings, thus suiting differing task demands without extensive retooling.

The integration of clever modern technology and IoT (Internet of Things) right into making procedures likewise adds to operation efficiency. Many modern-day perforation makers include features such as real-time monitoring and information analytics capacities, equipping operators to make informed choices concerning upkeep, production speed, and top quality control. This not just enhances operations but can likewise result in predictive upkeep, decreasing downtime by addressing possible problems before they escalate right into considerable issues.

As the market for made metal products remains to expand, the demand for efficiency, accuracy, and versatility in metal processing tools ends up being paramount. The advancement from out-of-date, manual procedures to automated systems promotes this demand by permitting suppliers to maximize their operations and result. Particularly, the capability to quickly adjust to changing layout demands or manufacturing quantities through modular systems in equipments like the coil perforation line has actually transformed how services operate.

Equipments like the metal wall panel machine and perforated devices have the possible to minimize waste product via extra efficient layouts and processing techniques. Responsible makers are finding methods to reuse scrap metal produced throughout the perforation and forming processes, therefore decreasing their total carbon footprint.

Moreover, as industries pursue even more green options, the metals utilized additionally develop. The trending preference for recycled steels and eco-friendly materials highlights another layer of complexity in the equipment made use of for metal processing. Modern equipment need to not just suit typical metal types but also adapt to the nuances provided by brand-new, lasting products while keeping performance and quality.

As we want to the future of metal construction, the continual growth of equipments such as the ceiling T-grid machine and the metal ceiling perforation line will certainly play a key role fit market criteria and practices. The ongoing development in automation, combined with sophisticated product scientific research, placements manufacturers to explore innovative opportunities in style and building and construction that were formerly unattainable.

Ultimately, the interconnected environment of equipment-- incorporating the sheet metal perforating machine, metal sheet leveling machine, and others-- develops a setting ripe for progress. By embracing these technological developments, makers are not just improving their manufacturing abilities however are likewise establishing a brand-new frontier of what is feasible in metal construction. The harmony of accuracy design, automation, and clever modern technology is making it possible for organizations to grow in an affordable landscape, therefore preparing for an extra reliable and liable production future.

The value of coil perforation lines can not be overemphasized, as they assist in the handling of metal coils right into functional sheets or parts with pre-determined openings. This procedure substantially improves the versatility in style and application, providing to varied sectors such as construction, automotive, and home appliances. The precision provided by such machines guarantees that each perforation is performed with accuracy, thus decreasing waste and maximizing resource application. Paired with innovations in innovation, today's sheet metal perforating machine can accomplish broadband and performance, allowing for large-scale production without endangering top quality.

The combination of wise technology and IoT (Internet of Things) into making procedures likewise adds to operation effectiveness. Numerous modern perforation machines feature attributes such as real-time tracking and data analytics capabilities, encouraging drivers to make educated decisions concerning upkeep, production speed, and top quality control. sheet metal perforating machine This not just improves operations yet can additionally result in predictive upkeep, minimizing downtime by resolving prospective issues prior to they intensify into substantial problems.

In verdict, as we reflect on the relevance of machines like the metal wall panel machine, metal ceiling perforation line, and various other relevant devices, it is clear that they stand for much even more than mere tools; they personify the capacity for technology and progress in the metalworking market. With proceeded investment in these modern technologies, the future of metal processing looks appealing, supplying exciting opportunities for both manufacturers and end-users alike.

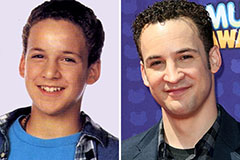

Ben Savage Then & Now!

Ben Savage Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!